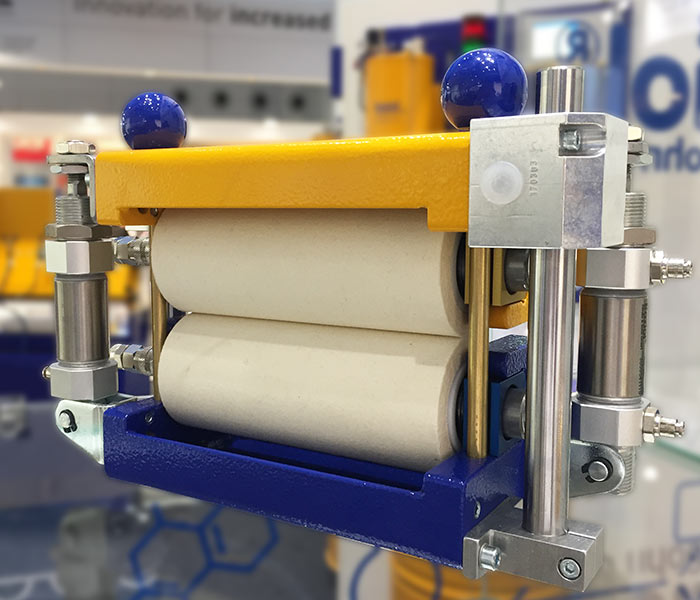

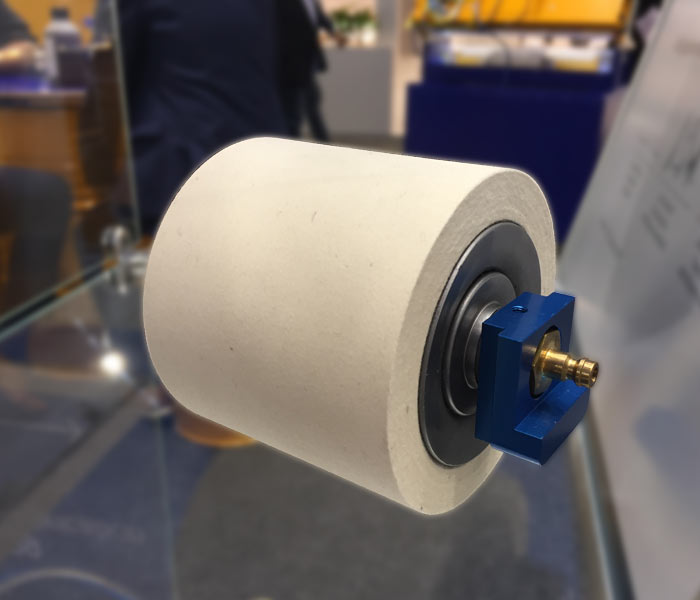

Roller application (contact lubrication)

Contact lubrication (roller application) signifies the oiling / lubrication of sheet metal surfaces by rolling the lubrication rollers over the coil material or onto blanks. Contact lubrication is performed principally without any generation of undesirable oil mist. Raziol is globally renowned for their environmentally-friendly roller lubricators applied in the process of contact lubrication (roller application) of sheet metal surfaces.

The classic Raziol roller lubrication systems include roller lubricators (RB), sector lubrication systems (SBA), blank lubricator systems (PBA) and calender lubricators (KW), and are all available in the most diverse configurations.

These systems are used for the oiling / lubrication of coil material (coils), blanks and round plates in non-cutting production technology, such as for deep drawing, stamping, fineblanking, bending and profiling, as well as in roller mills. They facilitate a reproducible, oil mist-free, inexpensive and automated application of lubricants onto numerous types of sheet metal surfaces.

English (UK)

English (UK)  Français (France)

Français (France)  Deutsch

Deutsch  Español (España)

Español (España)  Polski (PL)

Polski (PL)  简体中文(中国)

简体中文(中国)